What is Glass Sealing?

Glass sealing is typically used to seal insulators and metal together hermetically. For example, in the case of sealing metal pins such as signal wires to glass, Kovar glass, and Kovar metal (Fe:Ni:Co = 54:29:17) are heated and welded together.

This method takes advantage of the similarity of the thermal expansion coefficients of the base materials but has the disadvantage of being vulnerable to external forces (impact, shrinkage, and others). However, since there are no restrictions on the shape or sealing method, it is also superior to ceramic sealing.

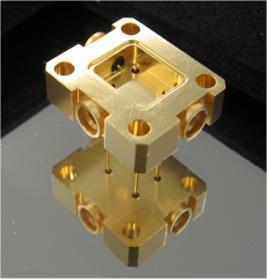

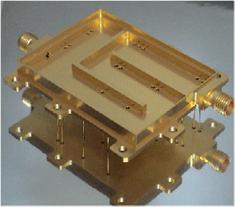

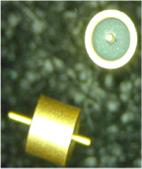

Samples of Sealed Products

RF Package |

Terminal for Millimeter Wave |

High-Pressure Vessel |

Combination of Metal Sealing

| Base | Lead | Type of Glass | Finishing | |

| Matched Seals | Kovar | Kovar | Borosilicate Glass | Ni-Ep+Au-Ep |

| Copper/Tungsten | Kovar | Borosilicate Glass | Ni-Ep+Au-Ep | |

| Compression Seals | Steel | Fe-Ni50% | Soft Glass | Ni-Ep+Au-Ep |

| Steel | Copper-Clad | Soft Glass | Ni-Elp | |

| Stainless Material | Fe-Ni50% | Soft Glass | Ni-Ep |

Handling Items

1. Multi-conductor header

2. Millimeter-wave band (DC-110GHz) terminal

3. Heat sink header assy

4. Hermetic sealing for high-pressure vessel

5. Customized products

Process Flowchart (Integrated Production System)

Process Flowchart (Integrated Production System)

1. Purchase raw materials =>

2. Machining process =>

3. Sealing =>

(4. Silver soldering)

(Press, M/C, Turning process)=>

5. Surface treatment =>

6. Quality check =>

7. Delivery

Facilities for Sealing

– Tunnel Kiln: 7

– Helium leak tester: 2

– Super insulation resistance test

Quality Assurance

To ensure a high-quality standard of hermetically sealed products, we perform various inspections and QA programs. These processes include inspections below, which comply with MIL-STD-883, MIL-PRF-38534, JEDEC No. 9, and Telcordia Standard.

Inspections include:

– Air-tightness

– Helium leak (with mass analyzer)

– Electrical insulating properties

– Electric property (high potential and dielectric resistance)

– Abrasion of a lead line

– Visual and dimensional check

– Solder wettability

– Thermal shock

![[KMCO] Kawashima Manufacturing Co., Ltd.](http://kmco.co.jp/en/wp-content/uploads/KMCO-top60.jpg)