Microwave/Millimeter-Wave and Coaxial Connectors

Waveguides were generally used for the transmission lines for microwave and millimeter-wave a while ago. In general, coaxial lines have such characteristics that if the frequency is higher, transmission loss becomes more substantial.

As the world’s technology advances, coaxial lines using low-loss dielectrics and precision machine tools that enable even more precise processing are widespread. For this reason, coaxial connectors for higher frequencies are being standardized one after another.

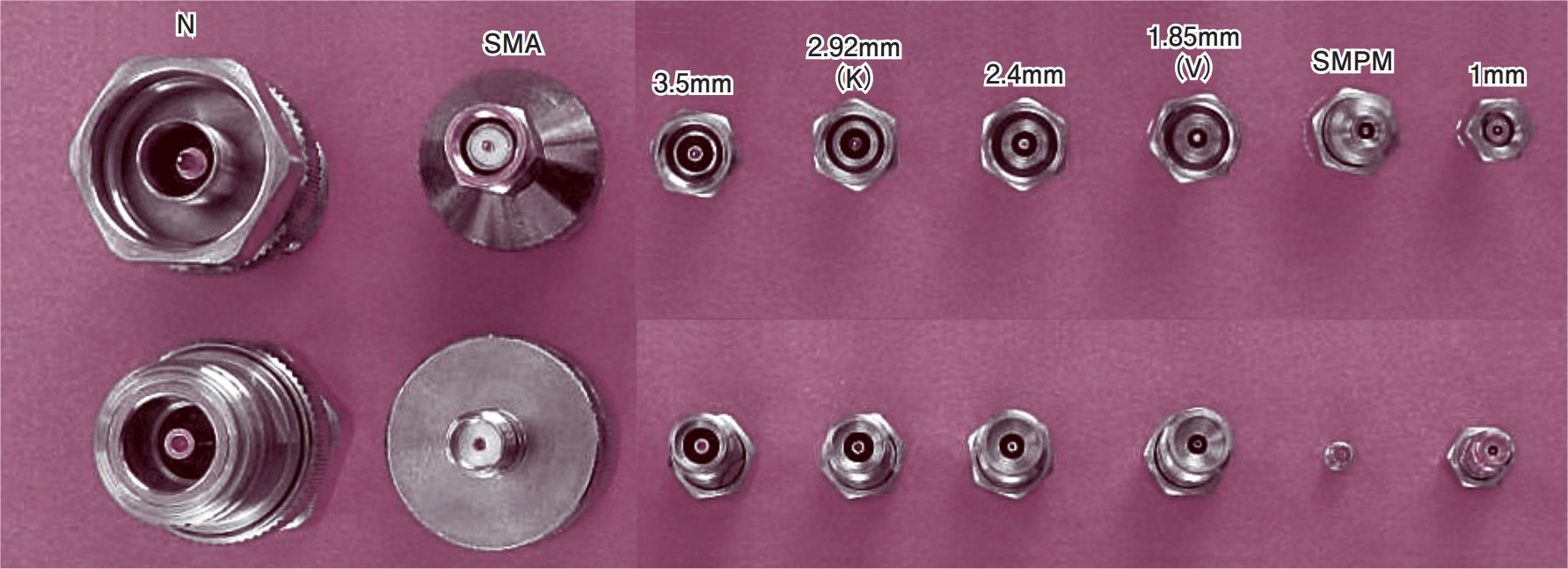

As a coaxial connector that can be used up to the millimeter-wave band, a precision connector conforming to the IEEE (Institute of Electrical and Electronics Engineers) standard is generally known.

Specifically, 3.5mm connectors with a maximum frequency of 26.5GHz, 2.92mm connectors at 40GHz, 2.4mm connectors at 50GHz, 1.85mm connectors at 65GHz, and 1mm connectors at 110GHz belong to this group.

Sometimes 2.92mm connectors are referred to as “K connector,” and 1.85mm connectors are referred to as “V connector.” However, please be aware that these names are trade names of Wiltron Corporation of the United States (current Anritsu Corporation), and they are not generic names.

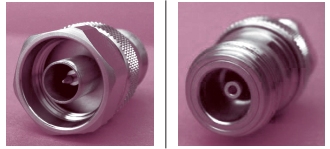

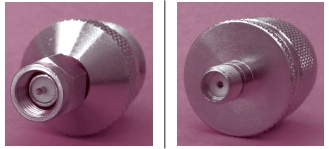

Another microwave/millimeter-wave coaxial connectors include N-type connectors, SMA connectors, push-on type SMP connectors, and SMPM connectors, specified by the US MIL standard. The N-type and SMA-type are widely used in commonly available wireless devices.

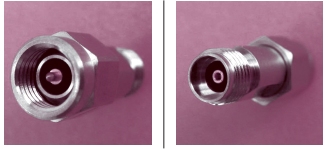

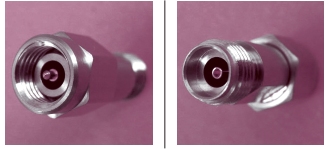

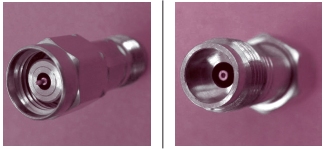

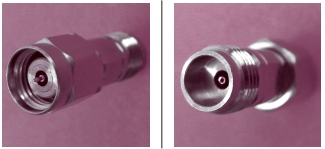

<Image> Coaxial connectors used in microwaves and millimeter waves

We have achieved high-precision and high-performance coaxial connectors with our design technology and advanced manufacturing technology cultivated over many years.

<Table> Types of coaxial connectors and part numbers in our company

| Connector Name | Frequency Upper Limit (Theoretical Value/General Value) |

Standard | Adapter Mating Surface (Male/Female) | Our Part Number |

| N | 19.4GHz/ 18GHz |

MIL, IEEE |  |

N |

| SMA | 25.1GHz/ 18GHz |

MIL |  |

SMA |

| SMP | 43.5GHz/ 40GHz |

MIL | – | – |

| SMPM | 66GHz/ 65GHz |

MIL |  |

SMPM |

| 3.5mm | 38.8GHz/ 33GHz |

IEEE |  |

KPC350 |

| 2.92mm | 46GHz/ 40GHz |

IEEE, MIL |  |

KPC292 |

| 2.4mm | 56.5GHz/ 50GHz |

IEEE, MIL |  |

KPC240 |

| 1.85mm | 73.3GHz/ 65GHz |

IEEE |  |

KPC185 |

| 1mm | 135.7GHz/ 110GHz |

IEEE |  |

KPC100 |

Note: The frequency upper limit (general value) differs in each manufacturer.

IEEE Compatible Precision Connector

Center Conductor Durability

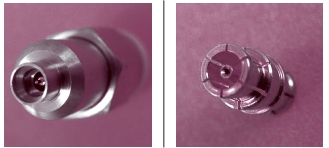

In most coaxial connectors, the center conductor slides, and the outer conductor is screwed to the other end. When we use the connectors with the standard method, these two sections will be worn out by repeated mating.

As long as the screw is tightened to the specified torque value, it is unlikely that the connector breaks easily. Also, if a center conductor is used in a normal way, the socket of a female connector does not excessively widen, and the pin of a male connector does not break, either.

However, mating connectors with different specifications are not assumed even for the combination of connectors that can be mated.

For example, SMA connectors and precision connector KPC350 can be mated together. SMA connectors are inexpensive and are used in many situations. Nevertheless, due to SMA’s rough design and production, its characteristics are significantly different from those of KPC350.

Besides, please be aware that KPC350 may be broken in the worst case if they are mated with SMA since their manufacturing accuracy as parts are different.

IEEE Precision Connector Standard and Mating Test

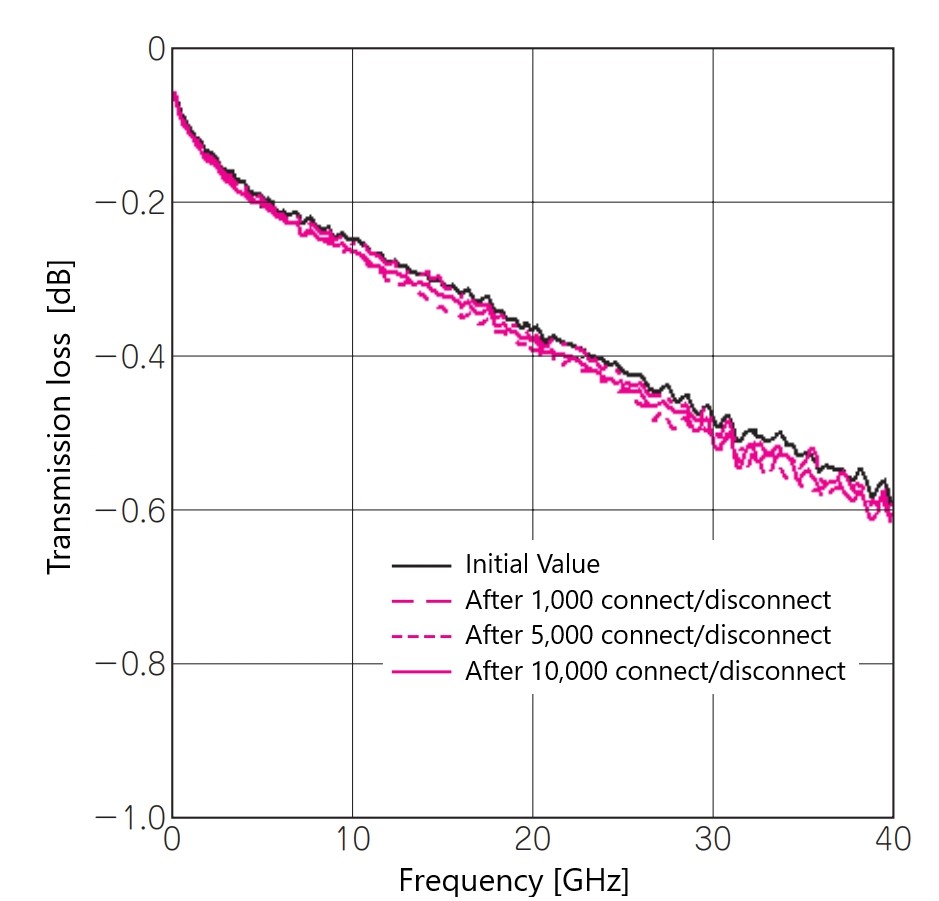

Under the IEEE precision connector standard, the life cycle of precision connectors due to connect/disconnect is determined as 2,000 to 5,000 cycles or more. Therefore, the electrical characteristics of the connectors should remain the same even after that much-repeated connect/disconnect.

We conduct experiments to compare electrical characteristics before and after repeated connect/disconnect of a center conductor 10,000 times.

“KPC Series” and Future Developments

We are proud and confident to offer our precision coaxial connector “KPC Series” to our customers as products with high-frequency characteristics and reliability.

In addition, we will continue to develop products that will be at the forefront of the times, so please feel free to contact us for new requests or requirements for connectors that are not yet available in the world or extremely difficult to achieve.

We are also developing and offering completely non-magnetic coaxial connectors for quantum computers that can be used at cryogenic temperatures.

![[KMCO] Kawashima Manufacturing Co., Ltd.](http://kmco.co.jp/en/wp-content/uploads/KMCO-top60.jpg)